PMC Industries Model ERI-1600 Trigger Pump Capping Machine Nozzle Inserter (New, never installed)

(1) PMC Model ERI-1600 spindle pump trigger pump capping machine with HS-60 trigger pump sorter and model CO-3000Trigger pump Orienter

Description

Unit still sits on original skid, as project was cancelled.

(1) PMC Model ERI-1600 16 Spindle Rotary Trigger Pump

Capping Machine with HS-60 Trigger Pump Sorter

and Model CO-3000 Trigger Pump Orienter to apply

trigger spray pumps with diptubes to rectangular plastic

containers at operating speeds of up to 240 per minute.

(1) Horizontal Transfer Conveyor approx. 8ft. length with

LF820K3-1/4″ chain from CO-3000 to “C” track on ERI -8000.

(1) PMC Model BS-1200 Floor Level Bulk Supply Bin with elevating

conveyor to feed trigger spray pumps to Pump Sorter. Standard

electrical control system.

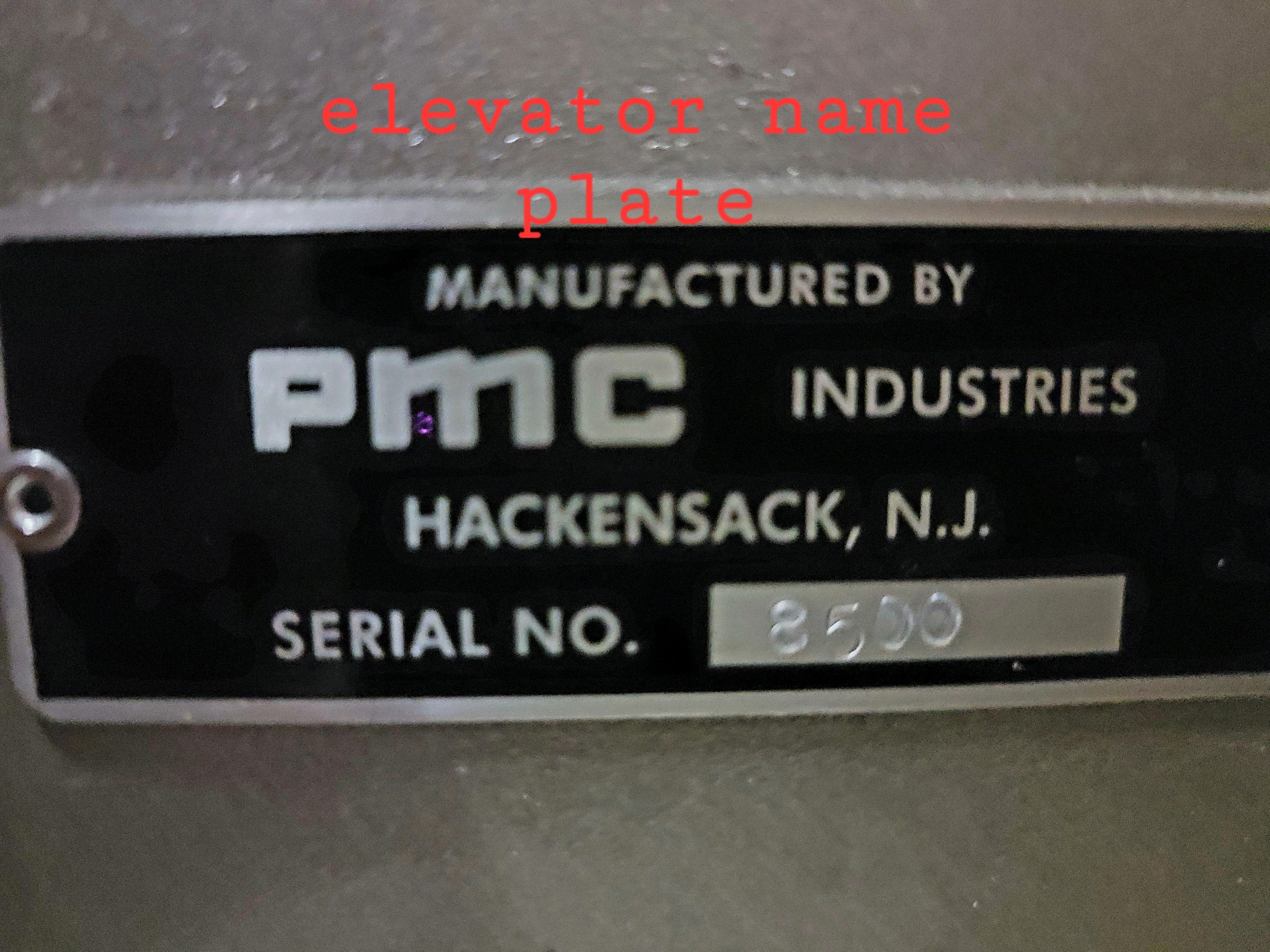

UPGRADE: bin volume of PMC Model BS-1200 (#8500) from:

20cu. ft. to 40 cu. ft.

ERI-1600 EQUIPPED WITH:

-Helix Infeed with safety overload clutch

-Infeed and discharge stars w/safety overloads

-Rotor star for rectangular containers

-PMC patented design diptube guides

-Specially designed chucks to hold pump heads oriented

-Trigger pump feed star with safety overload

-High limit P.E. on horizontal transfer conveyor

-Low limit P.E. on horizontal transfer conveyor

-Container backlog P.E. control on feed conveyor

-Container back-up P.E. control on discharge conveyor

-31-inch infeed conveyor w/ provision for straight through by-pass

-Stainless steel-clad tabletop with washdown capability

-Cluster lubrication fittings

-2 HP Drive motor, TEFC230/60/3

-Framed Lexan safety doors w/ safety interlocks

-Change parts to handle 32oz. rectangular container w/ trigger pump

-(2) Operation instruction manuals: hard copy and CD-ROM

HS-60 Sorter EQUIPPED WITH:

-Rotating transfer disk

-Diverter track

-Discharge guide track w/ automatic jam clearing

-Conveyor for re-cycle of jammed pumps back to supply bin

-1 HP Drive motor TEFC 230/60/3

-Safety interlocked access panel

CO-3000 Orienter EQUIPPED WITH:

-Metering star assembly w/drive

-Orienting wheel assembly w/ drive and speed control

-Mounting base

-Built-in rejection of pumps without diptubes

BS-2100 EQUIPPED WITH:

-20 cu. ft. bulk bin w/ clean out door

-Elevating conveyor 15″ wide

-Stainless Steel construction

-1/2 HP Drive motor TEFC230/60/3

-Control System to maintain pump sorter demand

Electrical Control System EQUIPPED WITH:

-PLC and Touch screen for status and control of all machines

-VFD’s for three motors

-Ethernet network

-Screen displays for all faults

-Backlog, backup, high limit, low limit, sorter level photo-eye controls

-Stainless steel junction box mounted in machine

-Main electrical control panel w/ proper heat dissipation properties, on stand-alone frame

-All hazardous areas interlocked

-Full documentation of all wiring

-Overloads wiring and display readouts of overloads

-START/STOP on ALL systems

-RUN/JOG Selector switch for jogging Capper

-Fault reset push button

-Emergency stop

-All wiring meets local and national standards

-Wiring between junction box and remote-mounted main box to be done on-site, by others